Equipment Enclosures

Durable. Hardened. Customizable.

Equipment Enclosures

Durable. Hardened. Customizable.

At Systems Control, we design, manufacture and test our turnkey equipment enclosures all under one roof.

Keeping all production processes in-house gives us control over the quality of materials, the workmanship and the timeline. This means you get a product that meets our strict standards in the least amount of time possible.

We have the capabilities to design Equipment Enclosures to your unique specifications for a truly customized solution. Because we manufacture our own enclosures, we aren’t dependent on an outside vendor’s constraints.

Custom Solutions for Every Utility

Watch this video to learn more about how Systems Controls remains nimble to our customer’s needs.

Integrated Solutions

Every component of your Equipment Enclosure is designed to work as a cohesive unit—not just a collection of different parts. Our assembly and wiring technicians complete every step with the pride and craftsmanship our customers have come to expect. All components, assemblies, and systems are then given a complete functional test to ensure they perform as an integrated whole and are in full compliance with our customer’s specifications.

Experience with:

• Protection & Control

• Switchgears

• Water Harvesters

• Sampler Stations

• Station Control Buildings

• Battery Enclosures

• Renewable Energy Buildings

Energy Storage Enclosures

Energy Storage Enclosures (ESE) require expert knowledge and experience. Safety is paramount – HVAC, Fire Protection and DC Protection are critical components to ensure the safe and effective operation of your Energy Enclosure System. Trust the leader in the utility turnkey enclosure industry to get it done right.

Experience with:

• Fire protection

• Thermal Design

• CFD Analysis

• UL Certification

• Seismic Design

• Multiple Battery Manufacturers

Hardened Enclosures

Hardened Turnkey Enclosures allow utility customers to leverage our concentrated expertise and integrated solutions to manage increasingly complex threats and regulatory requirements.

Hardened Enclosures protect across five pillars:

1 – Physical Attack: Up to level 8 ballistics rating

2 – Fire: Fire resistance designed to meet customer specifications

3 – Weather: Tornado and hurricane resistant

4 – EMP/EMI: Industry leading solutions

5 – Security: Physical access and cybersecurity

Outdoor Enclosures

If your project requires a small footprint, our outdoor and walk-in enclosures are a great, low-cost alternative to our Equipment Enclosures. Your enclosure will be custom-designed and built to meet your exact specifications, and all of our designs ensure easy access for field personnel from both front and rear. Advanced construction and insulation protect your valuable equipment from the elements, including extreme temperatures, condensation, ice, and snow.

Experience with:

• SCADA

• Telecomm

• Renewable Integration

• Protection & Control

• Station Power

• Mobile applications

The utility industry must understand that any substation, high-voltage transformer, or other equipment being shot at or subject to physical attack will be propelled into media scrutiny and a utility’s reputational risk could be altered.

— Director of NERC’s Electricity Information Sharing & Analysis Center

Turnkey Approach

No provider matches our range of end-to-end capabilities:

Engineering

We have Professional Engineer (PE) certified engineers prepared to handle your critical design projects. Your dedicated project manager and design team will work with you, from inception to installation.

Manufacturing

From raw steel to complete turnkey solutions – every cut, bend, weld, paint finish, crimp, and wire assembly is the subject of our constant attention to detail.

Integration

There are thousands of components and connections in an enclosure. You need them to fit together and work seamlessly to provide the solutions you need. Use the company that does it all under one roof and takes testing all the way to pre-commissioning in-factory.

Testing

We perform full functional testing of our panels and enclosures. Our objective is to catch every issue—whether they are the result of customer drawings, component suppliers, or customer outsourced engineering companies.

Installation

Our enclosures, control panels, and turnkey solutions are delivered in critical applications across the country. Using Systems Control’s patented METS enclosure delivery system we are able to deliver enclosures where others can’t. Our central location means we can deliver product for installation, anywhere in the continental US within 3-5 days of completion.

Quality isn’t a box to check, it’s a commitment

From start to finish, a relentless pursuit of perfection.

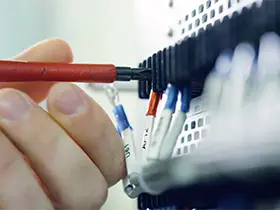

Wiring:

Cut to length, labeled and placed into individual harnesses with exacting precision – that’s Systems Control. Every connection we make is functional and durable with outstanding craftsmanship.

Crimping:

We take the extra step of testing every crimper, every shift, with every employee.

testing:

Panel wiring, building wiring and integration – all tested with our North American leading Utility Benchmark standard.

Certification:

ISO 9001:2015 certified through Intertek.

Safety Always

Safety Always is paramount to our business and our number one Core Value. It’s something we all own: every employee, every minute, every day.

From our facility to our customers’ job sites, we know the more time we spend ensuring every connection, every wire, every panel, and every enclosure is built to the highest standard, the safer we keep every worker.

It’s good business, and it’s simply the right thing to do.